Hey there, business owners and facility managers! Let’s talk about something that might not be the most exciting topic but is super important – keeping those big heat-making machines in your workplace clean and safe. When these systems get gunked up, they can cause big problems, from wasting energy to potentially dangerous situations. Regular industrial furnace cleaning helps prevent these issues and keeps your workplace running smoothly.

Why Regular Industrial Furnace Cleaning Is Critical for Safety

First things first, a well-maintained heating system just works better. When dust and debris build up inside your equipment, it has to work harder to do its job. This means your energy bills go up, but your heating efficiency goes down. Not a great combo, right?

But let’s talk about the really important stuff – safety. Did you know that built-up residue in heating equipment is a major fire risk? It’s true! When materials like dust, oil, and other gunk collect inside your system, they can ignite and cause serious problems. Industrial furnace cleaning removes these hazards before they become dangerous.

Plus, a dirty system can release harmful fumes into your workspace. Your team breathes this stuff all day, which can lead to health issues over time. Nobody wants that on their conscience!

Signs Your Furnace Needs Professional Cleaning Services

How do you know when it’s time to call in the pros? Look out for these warning signs:

- Higher than normal energy bills without explanation

- Uneven heating throughout your facility

- Strange sounds coming from your system

- Unusual odors when the system runs

- Visible soot or smoke marks around vents or equipment

If you notice any of these red flags, it’s probably time for some professional industrial furnace cleaning. Don’t wait until small issues become big problems!

Common Issues with Heat Exchangers and Ducts

The most frequent problems we see involve heat exchangers and duct systems. Heat exchangers can develop cracks when they get too dirty, which might allow dangerous gases to escape into your workspace. Not good!

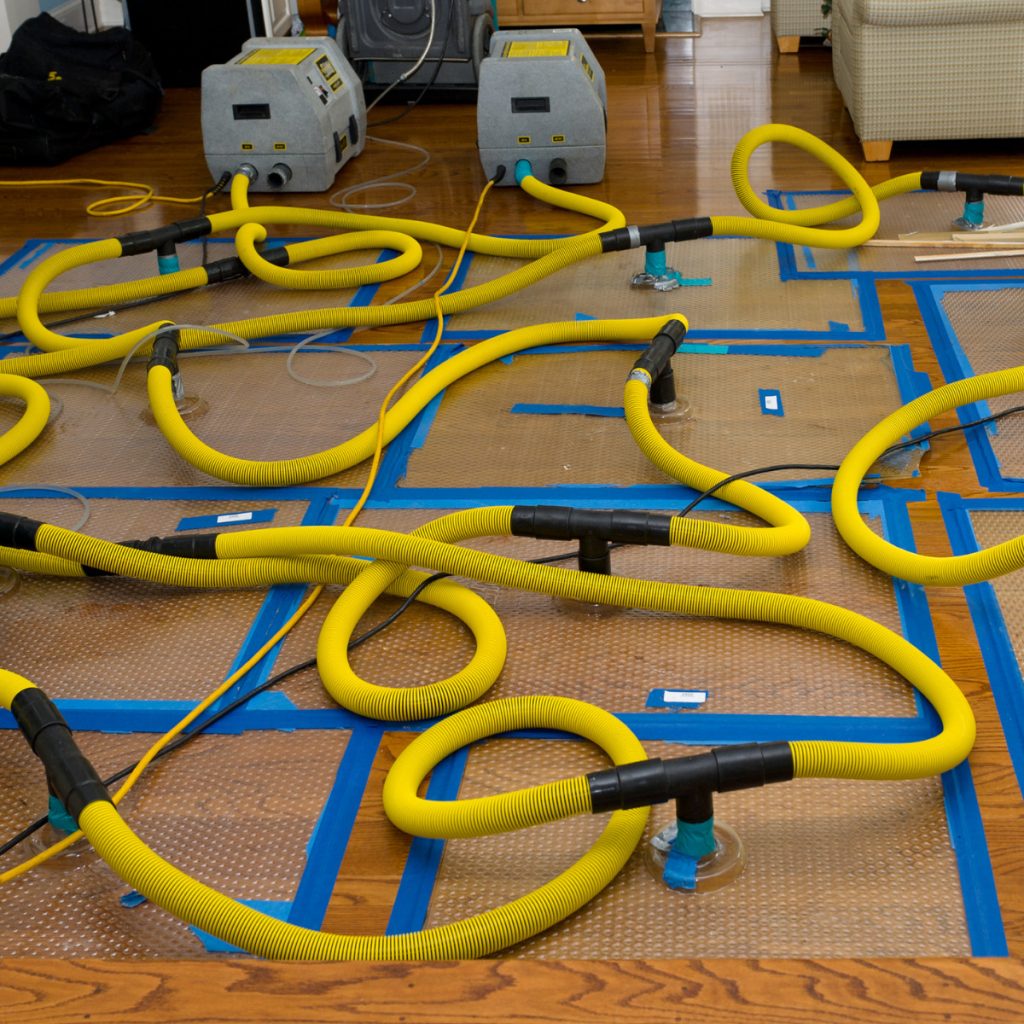

As for ducts, they’re like the highways of your heating system. When they get clogged with dust and debris, airflow gets restricted. This makes your system work harder and less efficiently. A thorough industrial furnace cleaning prevents these issues and keeps everything flowing smoothly.

The Complete Furnace Maintenance Process

A thorough maintenance process includes several key steps. First, we shut down and cool the system completely to ensure safety. Then, we remove access panels and begin inspecting all components.

Next comes the actual industrial furnace cleaning part. We use specialized tools to remove built-up residue from all internal components. This includes burners, heat exchangers, blowers, and other critical parts. We also check for wear and tear on components that might need repair or replacement.

The duct system gets special attention too. We clean these pathways to ensure proper airflow throughout your facility. Finally, we test everything to make sure it’s running at peak performance before we consider the job done.

Conclusion: How to Maintain an Industrial Furnace Long-Term

Setting up a regular maintenance schedule is the best way to keep your heating system in top shape. Most experts recommend professional industrial furnace cleaning at least once a year, but facilities with heavy use might need more frequent attention.

Between professional visits, your team can help too! Train staff to report any unusual sounds, smells, or performance issues right away. Keeping the area around equipment clean and free of dust and debris also helps prevent problems.

Remember, proper maintenance isn’t just about avoiding problems – it’s an investment in your facility’s efficiency, your employees’ health, and your bottom line. When your heating system runs properly, everybody wins!

Trustindex verifies that the original source of the review is Google. Ori & his assistant took before and after videos and thoroughly explained what needed to be cleaned. Did a great job—house vents smell clean now that bacteria has been removed!Posted onTrustindex verifies that the original source of the review is Google. Great efficient service!Posted onTrustindex verifies that the original source of the review is Google. Ori and his team did a great job identifying bacteria and cleaning it for me, as well as providing a solution to help with prevention. I appreciate him and his team!Posted onTrustindex verifies that the original source of the review is Google. Thank you Green Air Duct Club. You where on time and very through. Oren presented me with before and after photos that where a great help understanding what needed to be done. Thank you for great service and price. We are very Happy!Posted onTrustindex verifies that the original source of the review is Google. I was very impressed with the clarity and efficiency of the cleaning process; the professionals explained every detail and executed the work with great precision, leaving my home completely worry free.Posted onTrustindex verifies that the original source of the review is Google. I appreciated the transparent, clear communication from the team, who meticulously cleaned every vent and provided updates that made the entire air duct cleaning process completely worry free.Posted onTrustindex verifies that the original source of the review is Google. AhabahabbaPosted onTrustindex verifies that the original source of the review is Google. Green Air Duct did a wonderful job - cleaning and disinfect our air ducts and A/C unit. Ori was honest and up front about what we needed - and didn’t need. We had them look at the insulation in the attic as well, and despite aging and based on our electrical bill, explained that it was probably not necessary. Attached are before and after of inside of duct box.Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

FAQ

How do you clean your furnace by yourself?

For basic maintenance, first shut off power completely. Then, check and replace your filter regularly. Clean visible dust from vents and components. Always wear proper PPE like gloves and masks. Remember, DIY cleaning works for home units, not complex industrial systems.

Why are furnace inspection services important before cleanup?

Inspections identify hidden deposit buildup and refractory damage before cleaning begins. They pinpoint exactly which areas need attention, saving you time and money. Professionals can spot potential safety issues that untrained eyes miss, preventing dangerous situations during the cleaning process.

Should I hire a professional technician for my industrial furnace cleaning?

Absolutely! Professionals understand complex combustion systems and have specialized equipment most businesses don’t own. They’re trained to safely handle dangerous deposits and ensure proper operation afterward. For industrial furnace cleaning, DIY approaches risk equipment damage and serious safety hazards.