Why Air Duct Design Matters for Your HVAC System

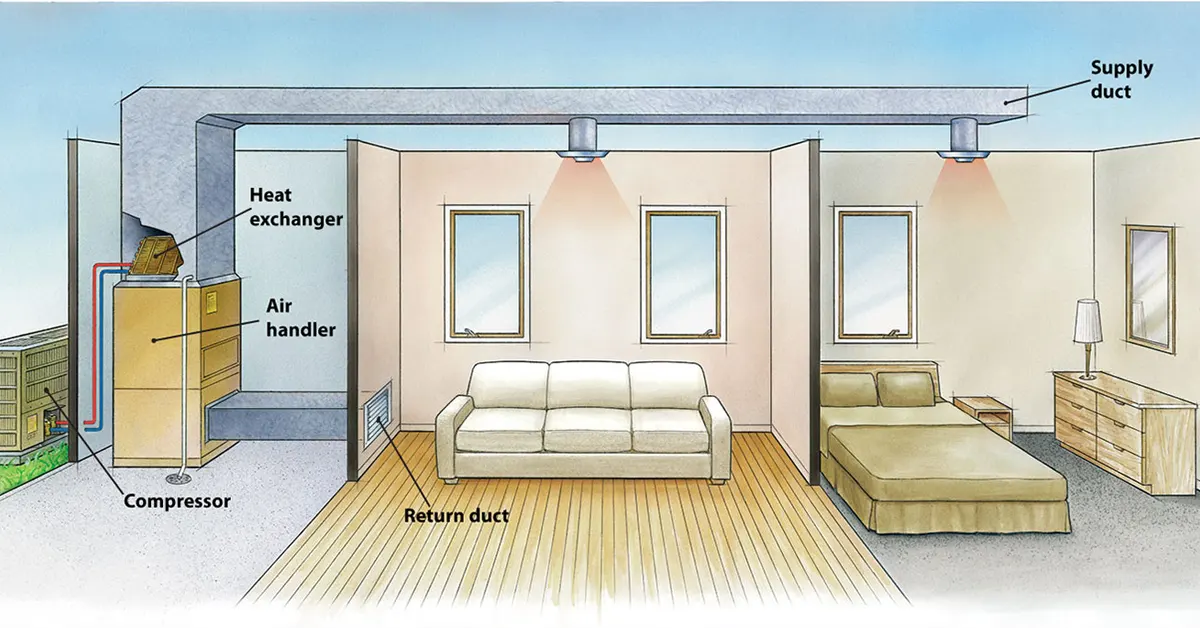

Understanding the Air Duct Design Process

The Role of Flex Duct and Ductwork in Your Home

Why Proper Size and Static Pressure Matter

Key Components: Registers, Insulation, and Dampers

Using Dampers for Better Air Distribution

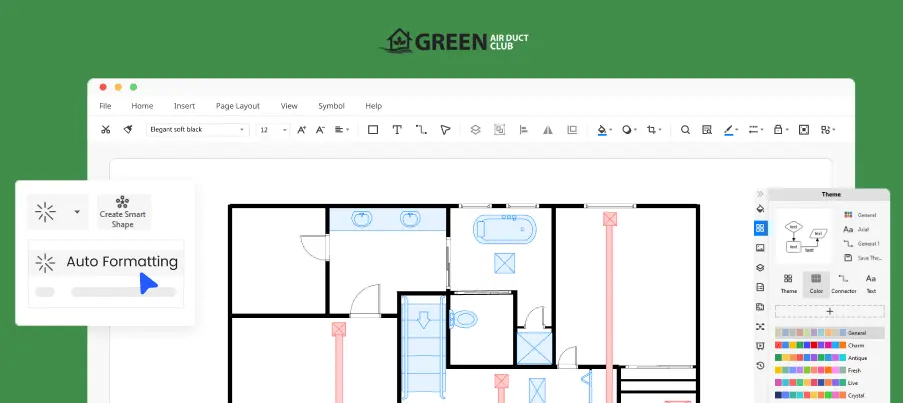

How HVAC Duct Design Software Improves Planning

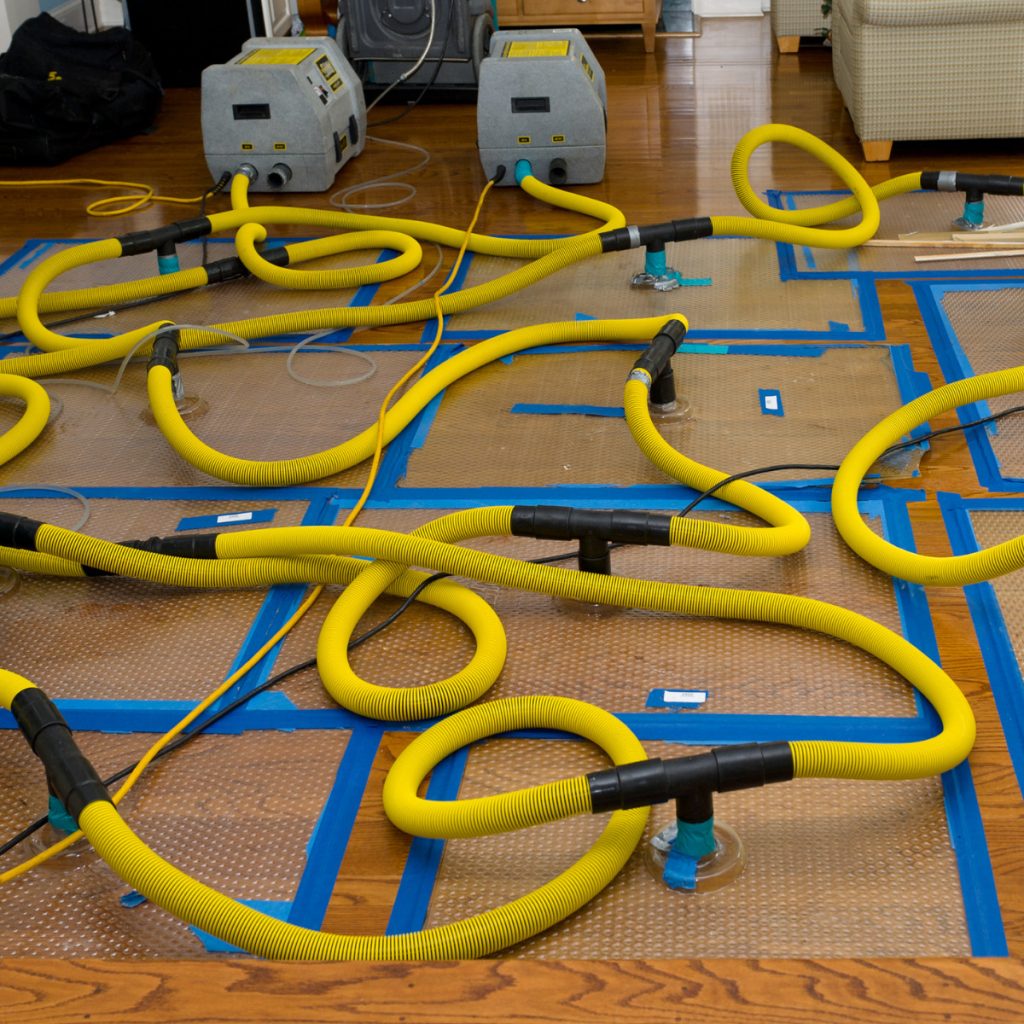

Improving Your Air Duct Design for Lasting Quality

Trust the Experts for Your Air Duct Design Needs

Trustindex verifies that the original source of the review is Google. Ori & his assistant took before and after videos and thoroughly explained what needed to be cleaned. Did a great job—house vents smell clean now that bacteria has been removed!Posted onTrustindex verifies that the original source of the review is Google. Great efficient service!Posted onTrustindex verifies that the original source of the review is Google. Ori and his team did a great job identifying bacteria and cleaning it for me, as well as providing a solution to help with prevention. I appreciate him and his team!Posted onTrustindex verifies that the original source of the review is Google. Thank you Green Air Duct Club. You where on time and very through. Oren presented me with before and after photos that where a great help understanding what needed to be done. Thank you for great service and price. We are very Happy!Posted onTrustindex verifies that the original source of the review is Google. I was very impressed with the clarity and efficiency of the cleaning process; the professionals explained every detail and executed the work with great precision, leaving my home completely worry free.Posted onTrustindex verifies that the original source of the review is Google. I appreciated the transparent, clear communication from the team, who meticulously cleaned every vent and provided updates that made the entire air duct cleaning process completely worry free.Posted onTrustindex verifies that the original source of the review is Google. AhabahabbaPosted onTrustindex verifies that the original source of the review is Google. Green Air Duct did a wonderful job - cleaning and disinfect our air ducts and A/C unit. Ori was honest and up front about what we needed - and didn’t need. We had them look at the insulation in the attic as well, and despite aging and based on our electrical bill, explained that it was probably not necessary. Attached are before and after of inside of duct box.Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Frequently Asked Questions

Q: How often should I have my air duct system inspected?

A: Schedule professional inspections every 3-5 years for optimal performance. If you notice reduced airflow, unusual odors, or increased dust, call sooner. Regular checks catch small issues before they become expensive problems. Systems in older homes or high-use environments benefit from more frequent attention.

Q: Can poor air duct design cause health problems?

A: Absolutely. Inadequate planning traps allergens, mold spores, and dust that trigger respiratory issues. Stagnant zones allow contaminants to accumulate and recirculate. Proper layouts maintain continuous movement that removes these irritants effectively. Better planning directly improves breathing quality and reduces allergy symptoms.

Q: What are signs that my air duct system needs redesigning?

A: Watch for uneven temperatures between rooms, excessive dust accumulation, or high energy bills. Whistling sounds from vents indicate pressure problems. Musty odors suggest moisture intrusion and possible mold growth. If your HVAC runs constantly without maintaining comfort, the layout likely needs professional evaluation.

Q: Is it worth investing in professional air duct design software calculations?

A: Yes, especially for new construction or major renovations. Software-based calculations prevent costly mistakes that manual estimates might miss. The investment pays back through lower energy costs and better comfort. Professional planning also ensures code compliance and optimal system longevity from the start.

Q: How much does it cost to redesign an existing air duct system?

A: Costs vary widely based on home size and complexity. Simple sealing and balancing might cost $500-$1,500. Complete redesigns with new pathways range from $3,000-$10,000 or more. Get multiple estimates from licensed contractors who perform detailed assessments. Many improvements deliver measurable savings that offset initial expenses over time.

Q: Can I improve my air duct system without complete replacement?

A: Often yes. Sealing leaks, adding insulation, and installing balancing dampers solve many problems affordably. Upgrading registers and adding zone controls also improve performance significantly. Professional assessment identifies which targeted improvements will deliver the best results for your specific situation and budget.