Your home’s heating system works hard during cold months. But here’s something most homeowners overlook. The liner inside your flue takes a beating over time. Cracks, gaps, and deterioration happen naturally with use. When this protective barrier fails, dangerous gases can leak into your home. That’s why chimney relining services matter so much for your family’s safety. I’ve worked on hundreds of these projects over the years. Trust me, catching problems early saves lives and money.

What Is a Chimney Liner and Why Does It Matter?

Think of your flue liner as a protective sleeve inside the stack. It channels smoke, gases, and heat safely out of your home. Without this barrier, extreme temperatures would damage the surrounding masonry. The liner also prevents carbon monoxide from seeping through cracks into living spaces.

Most homes built before the 1940s don’t have liners at all. Even newer homes may have damaged or deteriorating ones. I’ve inspected countless systems where homeowners had no idea their liner was failing. Quality chimney relining services restore that critical protective layer. This keeps combustion byproducts moving safely outside where they belong.

Signs You Need Flue Relining or Repair

So how do you know when it’s time for flue repair? Several warning signs point to liner problems. First, check for white staining on exterior bricks. This efflorescence indicates moisture penetration from inside. You might also notice a strong odor when using your heating system.

Another red flag is pieces of tile in your firebox. This means the clay tile liner is crumbling apart. Chimney relining services become urgent when you see this debris. Additionally, if you experience frequent downdrafts or smoke backing up, your liner likely has issues. Don’t ignore these symptoms – they indicate potentially hazardous conditions.

Visible Damage Around the Chimney System

Walk outside and examine the structure carefully. Look for cracked or missing mortar joints around the chimney. Water stains on interior walls near the stack signal problems, too. These issues often connect to liner deterioration deeper inside.

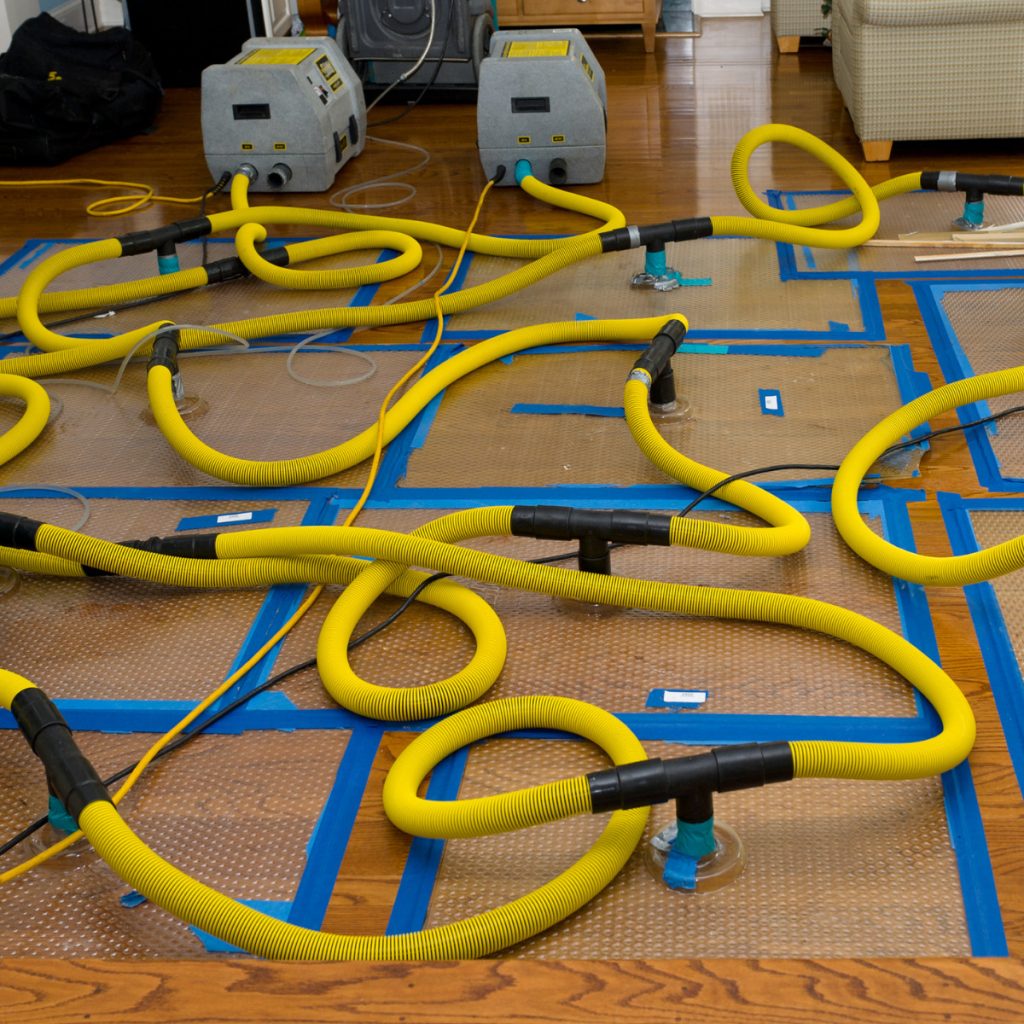

During inspections, I regularly find hidden damage homeowners never suspected. The exterior might look fine while the interior crumbles. Professional chimney relining services include thorough camera inspections. This technology reveals exactly what’s happening inside your flue system. Proper diagnosis leads to appropriate solutions for your specific situation.

Types of Chimney Flue Liner Options

When it’s time to reline a chimney, you have several material choices. Each type of chimney liner serves different needs and budgets. Understanding your options helps you make informed decisions. Let me break down the most common choices we install.

The three main options include stainless steel, clay tile, and cast-in-place materials. Your choice depends on fuel type, existing conditions, and budget. Chimney relining services professionals assess these factors during consultation. They recommend the best solution for your particular situation and heating equipment.

Stainless Steel Chimney Liner Benefits

A stainless steel liner offers excellent durability and versatility. These liners work with gas, oil, and wood-burning appliances. Installation typically goes faster than other methods, too. The stainless steel chimney liner comes with insulation options for improved efficiency.

I personally prefer stainless steel for most residential projects. Here’s why this option stands out:

- Flexible design fits irregular flue shapes easily

- Resists corrosion from acidic combustion byproducts

- Lifetime warranties are available from quality manufacturers

- Compatible with all fuel types

- Easier future chimney liner repair if ever needed

The insulation wraps around the liner, improving draft performance significantly.

Clay Tile Liner Considerations

Traditional clay tile liner systems have served homes for decades. They handle high temperatures well and last many years. However, clay tile comes with some limitations worth considering.

Installation requires more labor and time than stainless steel options. The rigid tiles don’t accommodate bends or offsets well either. When a clay tile liner cracks, replacement gets complicated. That said, chimney relining services using clay remain appropriate for certain applications. Straight, properly sized flues benefit from this proven material choice.

How Chimney Relining Services Protect Against Carbon Monoxide

Here’s where things get serious. Carbon monoxide kills hundreds of people annually. This invisible, odorless gas escapes through cracked or deteriorated liners. Even small gaps allow deadly fumes into your living space.

A properly installed chimney flue liner creates a sealed pathway. Combustion gases travel up and out without leaking into the walls. Professional chimney relining services ensure this seal remains intact. We test our installations thoroughly before finishing any job. Your family’s safety depends on this barrier working perfectly every single time.

Additionally, proper liner sizing affects combustion efficiency. An incorrectly sized flue causes incomplete burning. This produces more carbon monoxide than necessary. Expert chimney relining services match liner diameter to appliance requirements precisely.

Why Professional Chimney Relining Services Are Worth It

Some homeowners consider tackling flue relining themselves. I strongly advise against this approach. Working inside a narrow vertical space presents serious challenges. Special tools and training make this job manageable for professionals.

Improper installation creates more problems than it solves. Gaps, poor connections, and sizing errors compromise safety completely. Professional chimney relining services come with warranties and guarantees. Certified technicians follow manufacturer specifications exactly. This protects your investment and ensures code compliance for insurance purposes.

The cost of professional service seems high until you consider the risks. Medical bills, property damage, and liability far exceed service fees. Experienced teams complete most residential projects in one day. We handle permits, inspections, and cleanup so you don’t have to.

Trust the Experts for Chimney Relining Services

Your heating system deserves proper care from qualified professionals. Don’t gamble with your family’s safety on such critical work. Chimney relining services require specialized knowledge and equipment that most homeowners lack.

Choose a company with certified technicians and proven experience. Ask about their inspection process and material warranties. Quality providers explain options clearly without pressure tactics. They arrive on schedule and respect your home throughout the project.

When you need to reline your system, call professionals who do this daily. We’ve seen every type of chimney and know what works best. Protect your home, your family, and your peace of mind. Professional chimney relining services deliver results you can count on for decades.

Trustindex verifies that the original source of the review is Google. Ori & his assistant took before and after videos and thoroughly explained what needed to be cleaned. Did a great job—house vents smell clean now that bacteria has been removed!Posted onTrustindex verifies that the original source of the review is Google. Great efficient service!Posted onTrustindex verifies that the original source of the review is Google. Ori and his team did a great job identifying bacteria and cleaning it for me, as well as providing a solution to help with prevention. I appreciate him and his team!Posted onTrustindex verifies that the original source of the review is Google. Thank you Green Air Duct Club. You where on time and very through. Oren presented me with before and after photos that where a great help understanding what needed to be done. Thank you for great service and price. We are very Happy!Posted onTrustindex verifies that the original source of the review is Google. I was very impressed with the clarity and efficiency of the cleaning process; the professionals explained every detail and executed the work with great precision, leaving my home completely worry free.Posted onTrustindex verifies that the original source of the review is Google. I appreciated the transparent, clear communication from the team, who meticulously cleaned every vent and provided updates that made the entire air duct cleaning process completely worry free.Posted onTrustindex verifies that the original source of the review is Google. AhabahabbaPosted onTrustindex verifies that the original source of the review is Google. Green Air Duct did a wonderful job - cleaning and disinfect our air ducts and A/C unit. Ori was honest and up front about what we needed - and didn’t need. We had them look at the insulation in the attic as well, and despite aging and based on our electrical bill, explained that it was probably not necessary. Attached are before and after of inside of duct box.Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Frequently Asked Questions

Q: How often should I have my liner inspected?

A: Most homes benefit from professional cleaning every three to five years. However, humid climates or homes with moisture issues may need more frequent service. If someone in your household has respiratory conditions, consider cleaning every two to three years. After water damage or flooding, schedule cleaning immediately, regardless of your regular maintenance cycle.

Q: Can I use my heating system while waiting for repairs?

A: We strongly recommend against using a damaged system. Cracked or deteriorated liners allow dangerous gases into your home. Even small gaps create carbon monoxide risks. Wait until professionals complete repairs and verify safe operation.

Q: What's the lifespan of different liner materials?

A: Stainless steel liners last 15 to 25 years with proper maintenance. High-quality versions carry lifetime warranties from manufacturers. Clay tile liners typically last 50 years or more under ideal conditions. Cast-in-place options fall somewhere between these ranges generally.

Q: Will relining improve my heating system's efficiency?

A: Yes, properly sized liners significantly improve draft and efficiency. Better airflow means more complete combustion of fuel. This reduces waste and lowers heating costs over time. Insulated liners maintain flue temperatures for optimal performance year-round.

Q: How long does a typical liner installation take?

A: Most residential projects take between 4 to 8 hours. Stainless steel installations usually finish faster than clay tile work. Complex situations with difficult access may require additional time. Your technician provides a timeline estimate during the initial consultation. Weather conditions and permit requirements can also affect scheduling.